By Industry

Medical Device Parts Auto Parts Electronic Communication Parts Household Appliances Parts Motorcycle Parts Sports Equipment Parts Aviation Parts 3D Printer Parts

Exploring Injection Molding Technique

Johnhalm gives you an overview of CNC machining technology

Do You Know the Die Casting Technique?

Johnhalm participated in the 10th International (Shenzhen) Foundry Industry Exhibition in 2020

Johnhalm participated in the 2017 The 11th Guangzhou International Mold Exhibition

Electroplating is a common metal finishing technique that adds decorative and corrosion protection to metal products. Before electroplating, the surface treatment of raw materials is required to ensure the quality of electroplating.

Treatment Process:

a.Cleaning Treatment:

Soak raw materials in degreasing agent or detergent, clean the surface with a brush or spray gun to remove surface oil and impurities.

Soak raw materials in dilute acid solution to remove surface oxides and rust through chemical reaction.

soak the raw material in the activator to make its surface have good electrical conductivity, so as to facilitate the subsequent electroplating operation.

Soak the raw material in the electrolyte containing the metal ions to be electroplated. After electrification, the metal ions are reduced and deposited on the surface of the raw material to form a thin film of metal.

Clean the raw materials after electroplating to remove electrolyte and other residues.

Factory Tour

Storage Area: Casting Processing:

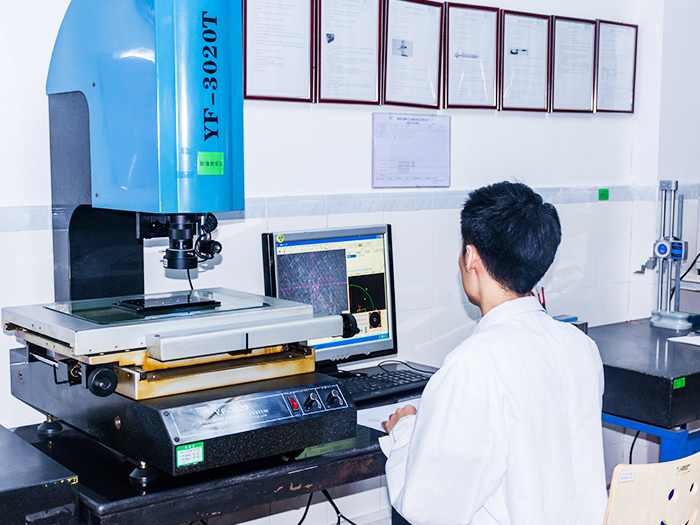

CNC Machining: Precision Measurement Room:

Packing: Team of Experts:

Whether you have a detailed drawing or just a concept in mind, we can customize the design and develop prototypes accordingly. Contact us and tell us your requirements for spare parts, our experts are ready to transform ideas into tangible products that meet your exact specifications..

Aluminum Die Casting Parts Zinc Die Casting Parts Plastic Injection Parts Magnesium Alloy Die Casting Parts Copper Alloy Die Casting Parts

Medical Device Industry Automotive Industry Motorcycle Industry Electronic Communication Industry Home Appliance Industry Fitness Equipment Industry Aerospace Industry 3D Printer